+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

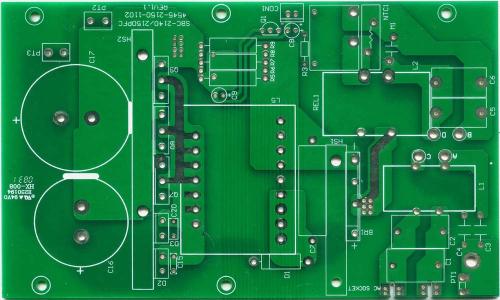

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-03-13

2024-03-13

520

520

1, PCB board width ≤260mm(SIEMENS line) or ≤300mm(FUJI line); If automatic dispensing is required, PCB board width × length ≤125 mm×180 mm.

2, PCB board appearance as close as possible to the conventional graphics, it is recommended to use 2*5, 3*3 board, can be assembled according to the thickness of the board;

3. The outer frame of the PCB assembly should adopt a closed-loop design to ensure that the assembly is fixed on the fixture without deformation.

4. The center distance between the small plates is controlled between 75 mm and 145 mm.

5. There can be no large components next to the connection point between the panel shape and the PCB internal small board, small board and small board, and the edge of the components and board should have a space greater than 0.5mm.

6, four positioning holes are opened at the four corners of the outer frame of the plate, plus the Mark point, the aperture is 4mm(±0.01mm); The strength of the hole should be moderate to ensure that it will not break during the process of upper and lower plates, and the hole wall is smooth without burrs.

7, in principle, the distance is less than 0.65mm QFP should be set in its diagonal position; The positioning reference symbols for PCB subboards should be used in pairs and arranged diagonally on the positioning elements.

8. When setting the reference anchor point, an open weld area 1.5 mm larger than the anchor point is usually set aside around it.

9, for some large components to leave positioning column or positioning hole, focus on such as I/O interface, microphone, battery interface, microswitch, headphone interface, etc.

Or call +86 755 2794 4155

Inquiry Now