+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-07-14

2023-07-14

877

877

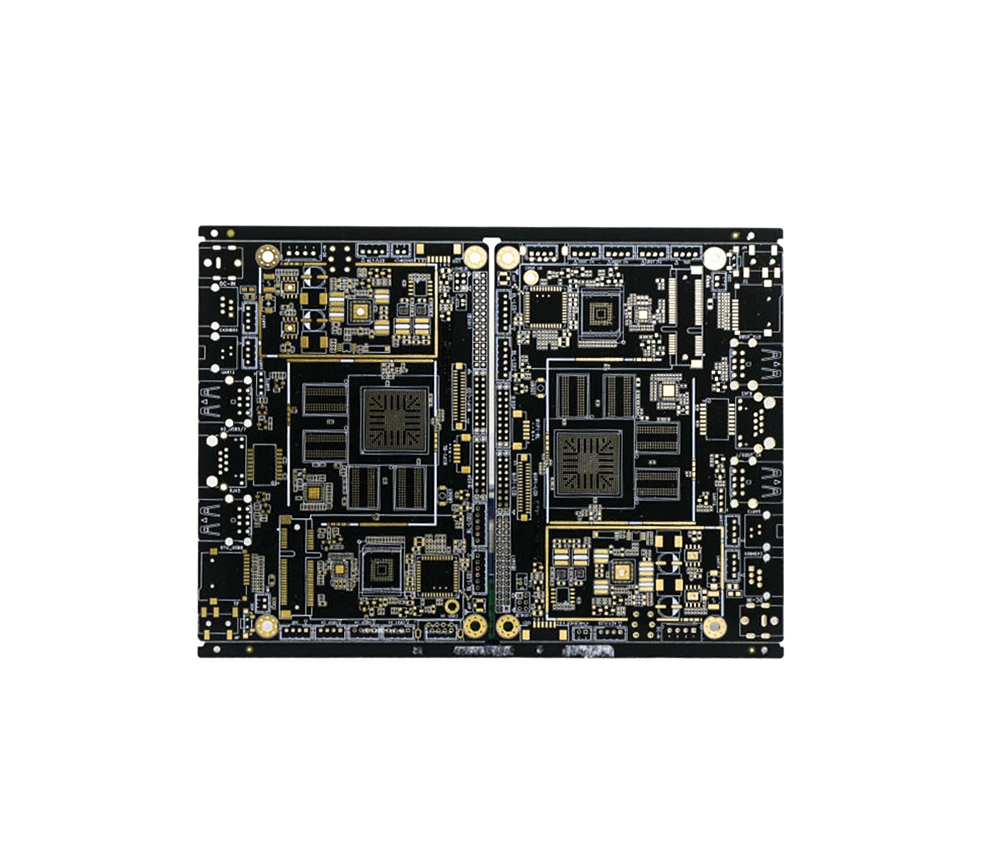

The drill head is first poured on the copper plate, and then passes through the chemical sinking copper, and the electroplating copper forms a coating hole. The two plays a vital role in the metal of holes.

1. Chemical sinking bronze machine:

In the process of double -sided and multi -layer printed board manufacturing, it is necessary to metallize non -conductive nude holes, that is, chemical sinking copper to make it a conductor. Chemical sinking solution is a catalytic "oxidation/restoration" reaction system. Under the catalysis of metal particles such as AG, PB, AU, CU, copper is deposited.

2. Copper plating mechanism:

The electroplating definition is to use the power supply to push the coating on the surface of the cathode on the surface of the cathode in the solution. Copper plating is a "oxidation/restoration" reaction. The copper metal anode in the solution oxidize the copper metal on its surface and become copper ions. On the other hand, a reaction is generated on the cathode, and copper ions are deposited into copper metal. Both are exchanged by potion, and the chemical effects achieve the purpose of holeization.

Or call +86 755 2794 4155

Inquiry Now