+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-01-10

2024-01-10

713

713

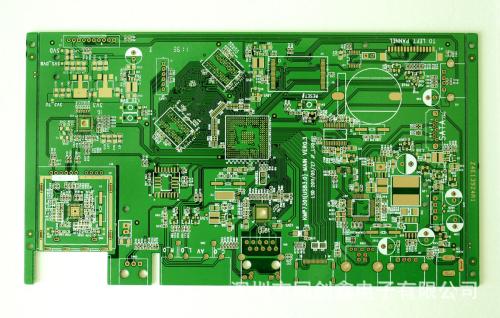

The volume of electronic products is becoming increasingly thin and short, and directly stacking holes on through blind holes is a design method to achieve high-density interconnection. To do a good job of stacking holes, the first step is to ensure the flatness of the hole bottom. There are several production methods, and the electroplating hole filling process is one of the representative ones. Next, let the PCB engineer teach you about the PCB electroplating hole filling process.

1. Advantages of electroplated hole filling:

(1) Beneficial for designing stacked holes and holes on the disc;

(2) Improving electrical performance helps with high-frequency design;

(3) Helps to dissipate heat;

(4) Plug holes and electrical interconnections are completed in one step;

(5) The blind hole is filled with electroplated copper, which has higher reliability and better conductivity than conductive adhesive.

2. Physical impact parameters

The physical parameters that need to be studied include: anode type, anode and cathode spacing, current density, agitation, temperature, rectifier, and waveform.

(1) Anode type. When it comes to the types of anodes, they are nothing more than soluble anodes and insoluble anodes. Soluble anodes are usually copper balls containing phosphorus, which can easily produce anode slime, contaminate the plating solution, and affect the performance of the plating solution. Insoluble anode, good stability, no need for anode maintenance, no anode slime generation, suitable for pulse or DC electroplating; But the consumption of additives is relatively high.

(2) The distance between the positive and negative poles. The spacing design between the cathode and anode in the electroplating hole filling process is very important, and the design of different types of equipment is also different. No matter how designed, it should not violate Faraday's first law.

(3) Stir. There are many types of stirring, including mechanical shaking, electrical vibration, pneumatic vibration, air stirring, jet flow, etc.

Or call +86 755 2794 4155

Inquiry Now