+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-02-23

2024-02-23

434

434

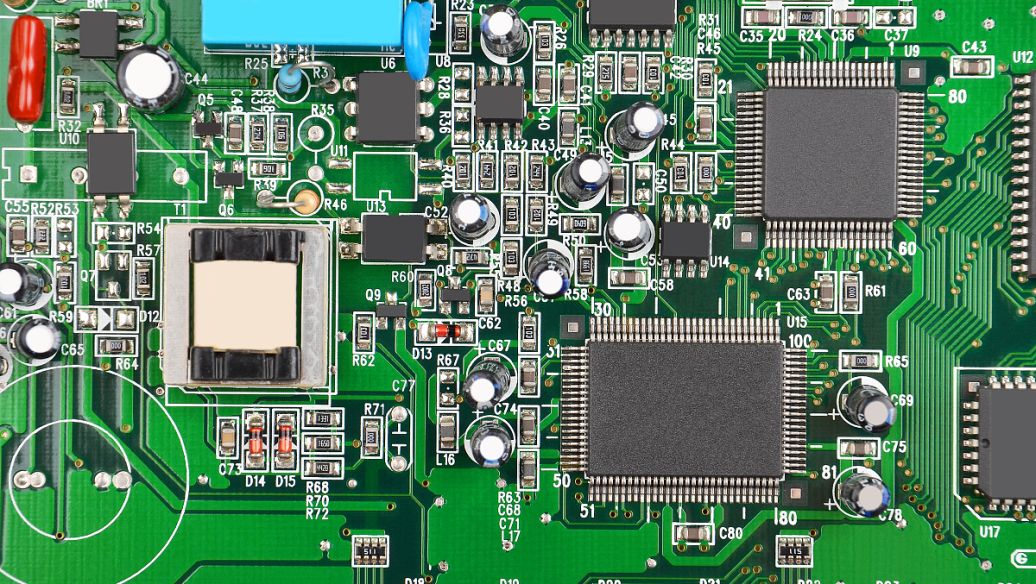

In the field of PCB, there are often many English terms that industry insiders may find difficult to fully recognize. How much do you know about PCB terminology? Let me introduce some commonly used terms in the PCB field to you:

1. FR4

In most cases, the glass fiber substrate for PCBs generally refers to the material "FR4". The solid material "FR4" gives PCB hardness and thickness.

Some cheap PCBs are made of materials such as epoxy resin or phenol, lacking the durability of FR4, but they are much cheaper. Phenolic substances have a lower thermal decomposition temperature, and excessive welding time can lead to their decomposition and carbonization, and emit unpleasant odors.

2. Copper

The thin copper foil layer on a PCB is pressed onto the substrate through heat and adhesive during production. On double-sided boards, copper foil is pressed onto both sides of the substrate. When we mention "double-sided board" or "two-layer board", we refer to two layers of copper foil on a thousand layers.

The thickness of the copper layer is generally represented by the weight of copper evenly covering one square foot (ounce oz). Most PCBs have a copper thickness of 1oz, but some high-power PCBs may use a copper thickness of 2oz or 3oz. Convert ounces (oz) per square foot to approximately 35um or 1.4mil copper thickness.

3. Soldermask

Above the copper layer is the solder mask layer. Generally speaking, solder mask is green, but almost all colors can be used for solder mask. The solder mask layer covers the wiring above the copper layer, preventing the wiring on the PCB from coming into contact with other metals, solder, or other conductive objects, resulting in short circuits. The existence of a solder mask layer allows everyone to weld in the correct place and prevents solder bridging.

Or call +86 755 2794 4155

Inquiry Now