+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-10-24

2023-10-24

864

864

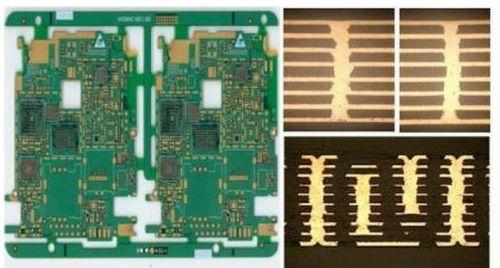

1. One on one assembly board

One on one splicing is the simplest splicing method, suitable for small PCB boards with a small quantity. Arrange each small board accurately on the large board according to the design requirements, then perform one-time etching, cutting, and other processes, and finally cut the large board into multiple independent small boards. This method is suitable for sample production or small-scale production, but it is inefficient for large-scale production.

2. Minimize Area Splicing

Minimizing area splicing is an optimized splicing method. Arrange multiple small boards on the large board in a certain way to minimize the area of the large board and save materials. This method is suitable for large-scale production, which can improve utilization and reduce costs.

3. Maximize the number of pieces for splicing

Maximizing the number of pieces is a splicing method that pursues production efficiency. According to the size and process requirements of the small board, by arranging and laying out reasonably, the free area on the large board is minimized to accommodate as many small boards as possible. This method is suitable for large-scale production and can significantly improve production efficiency, reduce production time and costs.

4. Mixed panel

Mixed splicing is the process of combining small boards of different sizes or designs onto a large board for splicing. By comprehensively considering the shape, size, and process requirements of different small boards, a reasonable layout is arranged to maximize the utilization of the area on the large board. This method is suitable for the production of different types of PCB boards and can improve utilization and flexibility.

Or call +86 755 2794 4155

Inquiry Now