+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-01-23

2024-01-23

495

495

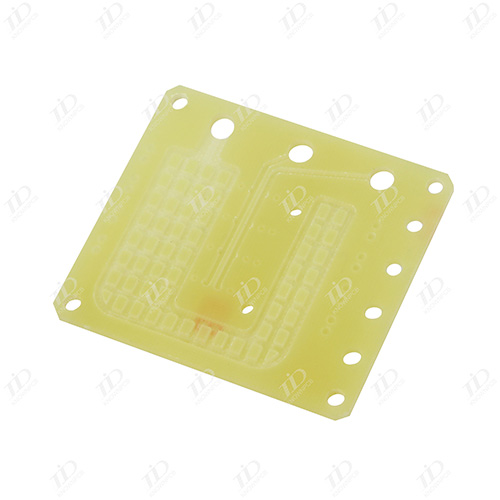

With the continuous development of the electronics industry, various electronic products are emerging one after another. Often, some customers demand unconventional thickness boards, such as 2.0mm, 2.4mm, 2.5mm, 3.0mm thick, etc. Can 3.0mm thickness boards be produced? The answer is revealed below, and the editor will explain it in detail below.

In order to ensure the integrity of product functionality, many customers choose thicker boards for production when their boards are used on equipment or when the components on the boards are heavy. The normal board thicknesses we produce are 0.6mm, 0.8mm, 1.0mm, 1.2mm, and 1.6mm. Some special products require thicker PCB boards. Use thicker PCB boards.

Can we ultimately make a 3.0mm thick PCB sample. The answer is certain, it can be produced. Our company often produces this type of board, and producing PCBs of this thickness is no longer a challenge in the industry. Only engineers need to pay attention when planning.

When planning, it is necessary to pay attention to the ratio of board thickness to minimum aperture. Currently, the board thickness to aperture ratio of Shenzhen Chengxuan Circuit Technology Co., Ltd. is 10:1, for example, if the board thickness is 3.0mm, then the minimum aperture should be greater than or equal to 0.3mm, and so on.

Why plan according to aperture ratio? There are many effects, and during the plugging process, this parameter is needed to select which plugging method to use, as well as to understand the difficulty of plugging. The larger the aspect ratio, the more difficult it is to fill the hole. This parameter should be used in other processes related to holes, such as drilling, hole copper plating, etc.

Or call +86 755 2794 4155

Inquiry Now