+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-02-26

2024-02-26

253

253

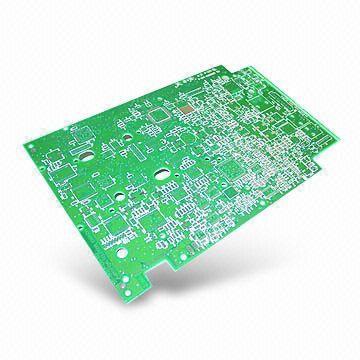

The circuit board and components undergo warping during the welding process, resulting in defects such as virtual soldering and short circuits due to stress deformation. Warping is often caused by temperature imbalance between the upper and lower parts of a circuit board. For large PCBs, the weight of the board itself can also cause warping. A regular PBGA device is about 0.5mm away from the printed circuit board. If the device on the circuit board is large, as the circuit board cools down and returns to its normal shape, the solder joints will be under stress for a long time. If the device is raised by 0.1mm, it is enough to cause a virtual solder open circuit.

In terms of layout, when the circuit board size is too large, although welding is easier to control, the printed lines are longer, the impedance increases, the noise resistance decreases, and the cost increases; If it is too small, the heat dissipation will decrease, and welding will be difficult to control, making it easy for adjacent lines to interfere with each other, such as electromagnetic interference from circuit boards. Therefore, it is necessary to optimize the PCB board design: (1) shorten the wiring between high-frequency components and reduce EMI interference. (2) Components with heavy weight (such as exceeding 20g) should be fixed with brackets and then welded. (3) Heating elements should consider heat dissipation issues to prevent significant surface damage to the components Δ Defects and rework caused by T should keep the thermistor away from the heat source. (4) The arrangement of components should be as parallel as possible, which is not only aesthetically pleasing but also easy to weld, making it suitable for mass production. The circuit board design is best with a 4:3 rectangle. Do not have sudden changes in wire width to avoid discontinuity in wiring. When a circuit board is heated for a long time, copper foil is prone to expansion and detachment. Therefore, it is advisable to avoid using large areas of copper foil.

Or call +86 755 2794 4155

Inquiry Now